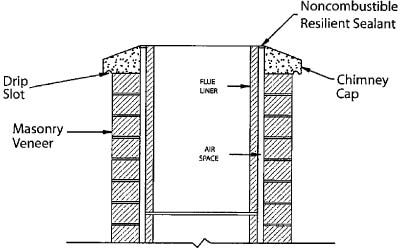

Chimney Cap Detail

6/18/11

|

Chimney caps should slope a minimum of 10 degrees downward from the flue liner to the edge of the chimney cap to shed water. Chimney caps should overhang the chimney wall by a minimum of 2 in. to provide a drip edge with a drip slot on the underside at least 1 1/2 in. away from the chimney wall. Concrete chimney caps should be reinforced with at least 1/2 in. mesh galvanized hardware cloth placed about midway in the concrete. Chimney caps must be separated from the flue lining which will move up and down when heated and break or lift off the cap if bonded to the cap. A a bond break is created by keeping the chimney cap at least 5/8" away from the flue lining and, when cured, sealing the 5/8" gap with a noncombustible resilient sealant to prevent water entering the chimney. A thinner expansion joint will tear away and fail. Most masonry materials dealers carry masonry expansion joint caulking or silicone sealants.

|

Masonry Chimneys

Buckley Rumford Fireplaces

Copyright 1995 - 2011 Jim Buckley

All rights reserved.